China Supplier Automatic Non Woven Bag Machine - The belt conveyor plus automatic counter system – TianXuan

China Supplier Automatic Non Woven Bag Machine - The belt conveyor plus automatic counter system – TianXuan Detail:

Typical Applications:

• Aerospace & Defense

• Automotive

• Electronics

• Hardware & Fasteners

• Healthcare

• Hobby & Craft

• Personal Products

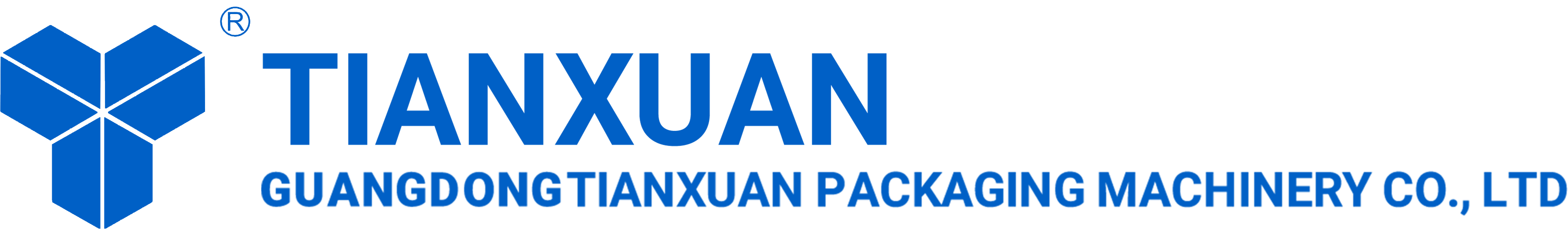

The Belt Conveyor Packing Machine Advantage

• Reduces labor cost while doubling packaging throughput, providing higher packaging productivity with fewer operators.

• Can be integrated with simple robotics for even faster packaging.

• Ideal system for hand-load kit packages and sub-assemblies, giving the operator the time and control of the system speed rates.

• Electronic Eye Counter and Accumulator signals bagger to cycle only when the machine flight contains product, preventing bag waste.

The Belt Conveyor Technical Data

| Model | LS-300 |

| Packing size | L: 30-180mm, W: 50-140mm |

| Packing material | OPP, CPP, Laminated film |

| Air supply | 0.4-0.6 MPa |

| Packing speed | 10-50 bag/min |

| Power | AC220V 2KW |

| Machine size | L 2000 x W 700 x H 1600mm |

| Machine Weight | 200 kgs |

It is a flexible, high-speed, high-accuracy, automatic counting, vibratory bowl feed system.

It is capable of counting and batching at speeds up to 2500 packages per hour.

The machine offers maximum 3 bowls configurations, allowing the flexibility to efficiently run a variety of parts.

An orientation funnel provides enhanced control of the parts as they pass through the detection eye, improving counting accuracy.

Speed and accuracy increased with the overcout discharge funnel which diverts excess parts away from the bag and into a holding bin.

Once the pre-determined count is reached, the product is funneled into a pre-opened bag, which is automatically sealed and dispensed, while another bag is indexed for loading.

The operator friendly control screen features easy job set-up job recall and on board system diagnostics.

Automatic Counter Technical Data

| Model | LS-200 |

| Packing size | L: 55-100mm, W: 20-90mm |

| Packing material | OPP, CPP, Laminated film |

| Air supply | 0.4-0.6 MPa |

| Packing speed | 10-50 bag/min |

| Power | AC220V 1.8 KW |

| Machine size | L 900 x W 1100 x H 2100mm |

| Machine Weight | 200 kgs |

It is a flexible, high-speed, high-accuracy, automatic counting, vibratory bowl feed system.

It is capable of counting and batching at speeds up to 2500 packages per hour.

The machine offers maximum 3 bowls configurations, allowing the flexibility to efficiently run a variety of parts.

An orientation funnel provides enhanced control of the parts as they pass through the detection eye, improving counting accuracy.

Speed and accuracy increased with the overcout discharge funnel which diverts excess parts away from the bag and into a holding bin.

Once the pre-determined count is reached, the product is funneled into a pre-opened bag, which is automatically sealed and dispensed, while another bag is indexed for loading.

The operator friendly control screen features easy job set-up job recall and on board system diagnostics.

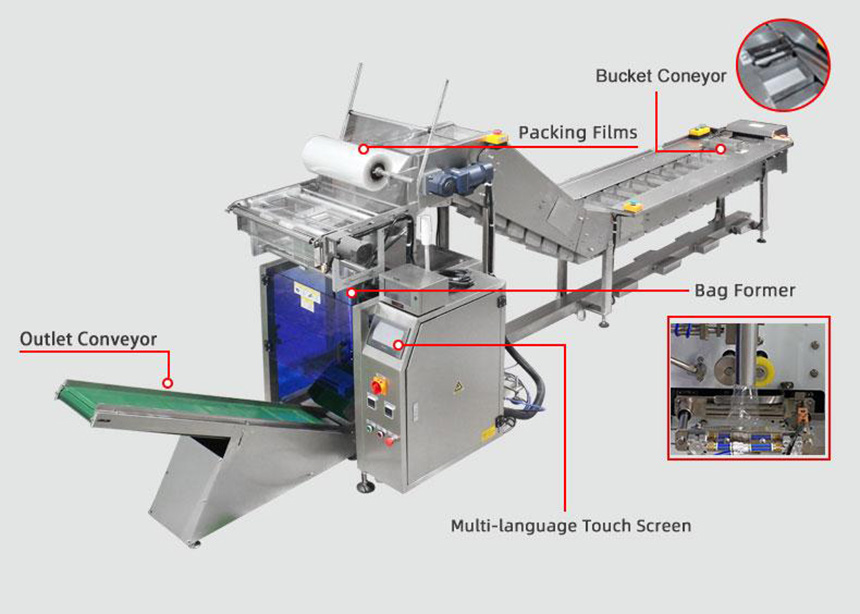

Voltage: AC100-240V 50/60Hz

Power: 2.0 KW

Air Source: 0.4-0.6MPA

Weight: 200 kg

Pouch Style: 3 side seal, Fin seal

Packaging capacity: 1-50 pouch per minute

Counting quanlity: 1-20pcs

Machine size: L1100*W700*H1600mm

Pouch size: L50-180mm W40-140mm

Product detail pictures:

Related Product Guide:

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for China Supplier Automatic Non Woven Bag Machine - The belt conveyor plus automatic counter system – TianXuan , The product will supply to all over the world, such as: Pakistan, Guinea, Cannes, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.