Good Quality Small Pouches Packing Machine - The belt conveyor plus automatic counter system – TianXuan

Good Quality Small Pouches Packing Machine - The belt conveyor plus automatic counter system – TianXuan Detail:

Typical Applications:

• Aerospace & Defense

• Automotive

• Electronics

• Hardware & Fasteners

• Healthcare

• Hobby & Craft

• Personal Products

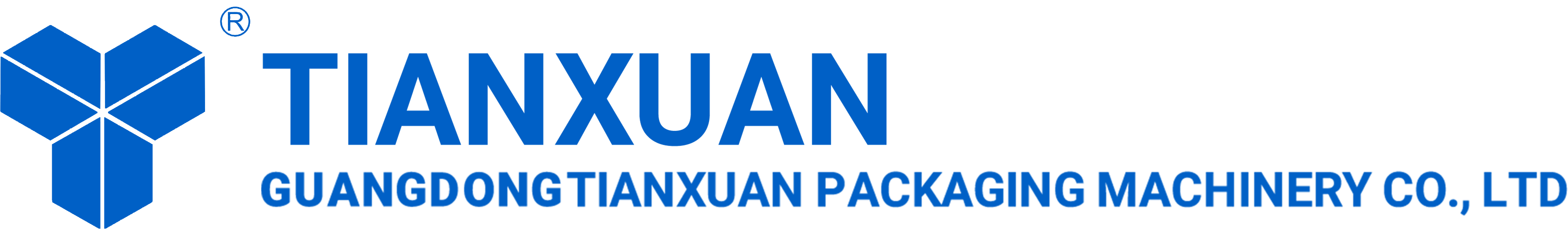

The Belt Conveyor Packing Machine Advantage

• Reduces labor cost while doubling packaging throughput, providing higher packaging productivity with fewer operators.

• Can be integrated with simple robotics for even faster packaging.

• Ideal system for hand-load kit packages and sub-assemblies, giving the operator the time and control of the system speed rates.

• Electronic Eye Counter and Accumulator signals bagger to cycle only when the machine flight contains product, preventing bag waste.

The Belt Conveyor Technical Data

| Model | LS-300 |

| Packing size | L: 30-180mm, W: 50-140mm |

| Packing material | OPP, CPP, Laminated film |

| Air supply | 0.4-0.6 MPa |

| Packing speed | 10-50 bag/min |

| Power | AC220V 2KW |

| Machine size | L 2000 x W 700 x H 1600mm |

| Machine Weight | 200 kgs |

It is a flexible, high-speed, high-accuracy, automatic counting, vibratory bowl feed system.

It is capable of counting and batching at speeds up to 2500 packages per hour.

The machine offers maximum 3 bowls configurations, allowing the flexibility to efficiently run a variety of parts.

An orientation funnel provides enhanced control of the parts as they pass through the detection eye, improving counting accuracy.

Speed and accuracy increased with the overcout discharge funnel which diverts excess parts away from the bag and into a holding bin.

Once the pre-determined count is reached, the product is funneled into a pre-opened bag, which is automatically sealed and dispensed, while another bag is indexed for loading.

The operator friendly control screen features easy job set-up job recall and on board system diagnostics.

Automatic Counter Technical Data

| Model | LS-200 |

| Packing size | L: 55-100mm, W: 20-90mm |

| Packing material | OPP, CPP, Laminated film |

| Air supply | 0.4-0.6 MPa |

| Packing speed | 10-50 bag/min |

| Power | AC220V 1.8 KW |

| Machine size | L 900 x W 1100 x H 2100mm |

| Machine Weight | 200 kgs |

It is a flexible, high-speed, high-accuracy, automatic counting, vibratory bowl feed system.

It is capable of counting and batching at speeds up to 2500 packages per hour.

The machine offers maximum 3 bowls configurations, allowing the flexibility to efficiently run a variety of parts.

An orientation funnel provides enhanced control of the parts as they pass through the detection eye, improving counting accuracy.

Speed and accuracy increased with the overcout discharge funnel which diverts excess parts away from the bag and into a holding bin.

Once the pre-determined count is reached, the product is funneled into a pre-opened bag, which is automatically sealed and dispensed, while another bag is indexed for loading.

The operator friendly control screen features easy job set-up job recall and on board system diagnostics.

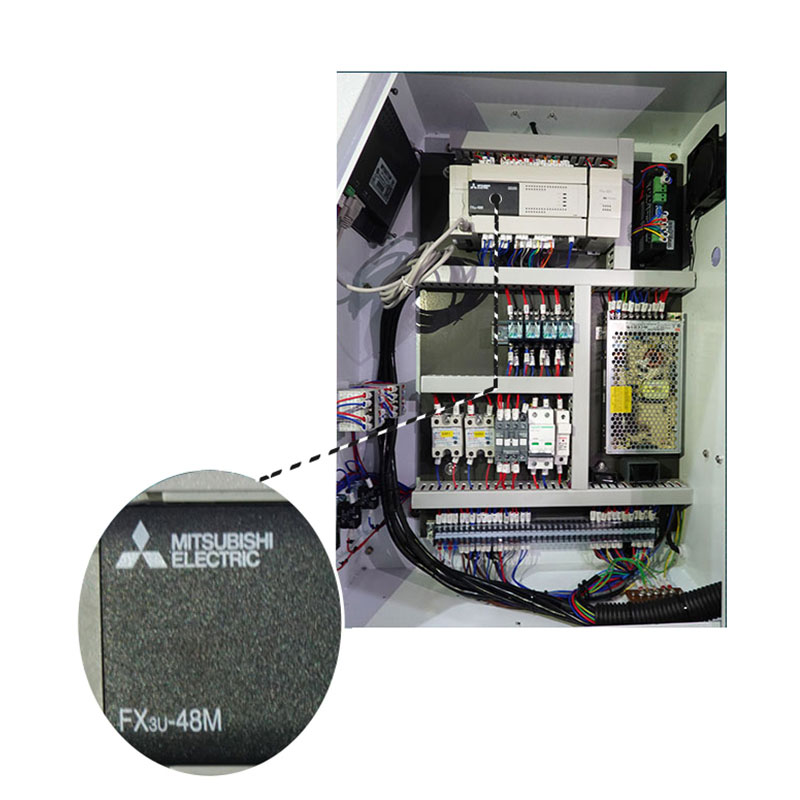

Voltage: AC100-240V 50/60Hz

Power: 2.0 KW

Air Source: 0.4-0.6MPA

Weight: 200 kg

Pouch Style: 3 side seal, Fin seal

Packaging capacity: 1-50 pouch per minute

Counting quanlity: 1-20pcs

Machine size: L1100*W700*H1600mm

Pouch size: L50-180mm W40-140mm

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Good Quality Small Pouches Packing Machine - The belt conveyor plus automatic counter system – TianXuan , The product will supply to all over the world, such as: Belgium, United Arab Emirates, Durban, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.