Quality Inspection for Horizontal Pouch Packing Machine - Intelligent Packaging Solution – TianXuan

Quality Inspection for Horizontal Pouch Packing Machine - Intelligent Packaging Solution – TianXuan Detail:

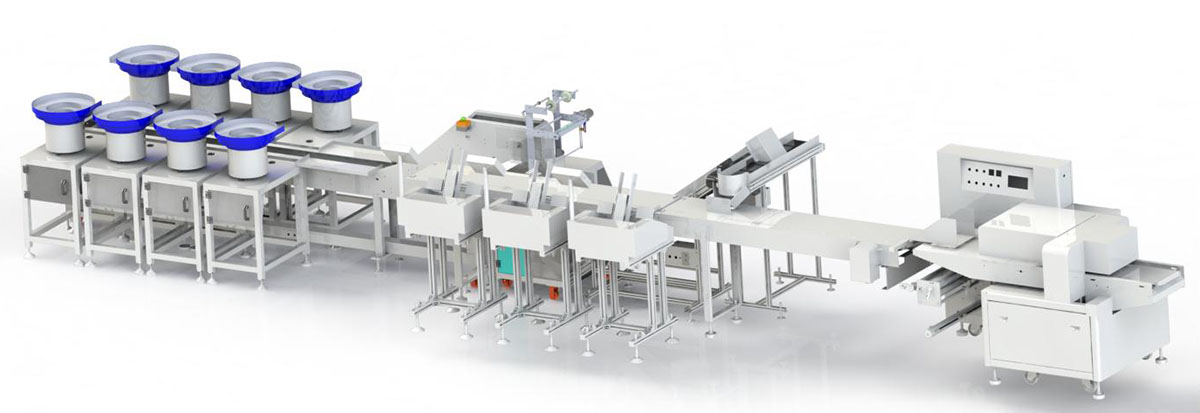

Intelligent Packaging Solution

We provide you with high quality automatic counting & packaging solutions.

The successful case as below:

Vertical Packaging Machine for single packaging first

Horizontal Packing Machine for secondary packing

Vertical packaging machine + horizontal packing machine can be operated in the same time.

Vertical Packaging Machine+Automatic Card Issuing Machine+Horizontal Packing Machine Combination

♦ Vertical Packaging Machine

Weighing and counting packing machine is suitable for variety of hardware parts and plastic parts. For example hardware parts, nuts, bearing, bolts, plastic parts, screws, fastener, bearings etc.

Features:

• This machine is applicable to single items packing and mixed 2-3 kinds of items packing, operating easily with PLC control system.

• Firm sealing, smooth and elegant bag shape, high efficiency and durability are preferred elements.

• Automatic ordering, counting, packing and printing can be offered.

• Equipped with exhaust device, printer, labeling machine, transfer conveyor and weight checker make it better.

♦ Horizontal Packing Machine

Application for automatic packaging for the below items:

• 3C home appliance manual

• Fruit & Vegetable

• Stationery

• Hardware

• Regular products

• Disposable mask and KN95 mask

Features:

1. Three Servo control, automatically detect product length and cut, operator needn’t to adjust the unloading working, saving time and saving films.

2. Human-machine operation, convenient and quick parameter setting.

3. Self diagnosis failure function, clear failure display.

4. High sensitivity optical electric color mark tracking &digital input cut position which makes the sealing&cutting more accurate.

5. Separate PID control to temperature, suitable for various packing materials.

6. Stopping the machine in selected position, no sticking to the knife and no waste packing film.

7. Simple driving system, reliable working, convenient maintenance.

8. All the controls are achieved by software, convenient for function adjusting and upgrading.

♦ Automatic Card Issuing Machine

Application: A whole stack of sheeted products such as postcard, hangtag, label, envelope, red envelope and etc, folding products such as instruction, propaganda poster and various folding products with different size, book-like products such as instruction, card book, notebook, cartoon book, magazine and various book-like products with different sizes, the machine can automatically separate and convey them to the conveyor belt one by one. It can not only be used in counting as scorecard separately, but also can be integrated into related equipments as automatic scorecard to cooperate with various kinds of packaging line such as pillow type packaging machine, stand up packing machine, automatic conveyor etc.

Features:

• Servo or step motor drive, the speed can be reaches 500 pcs /min.

• High sensitivity sensor, 100% accurate for points

• Easy to operate PLC & Touch screen

• Automatic alarming when card misses or no card.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Quality Inspection for Horizontal Pouch Packing Machine - Intelligent Packaging Solution – TianXuan , The product will supply to all over the world, such as: Slovakia, Mexico, Nigeria, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!